- InverterTop

- Inverter

- Inverter options (peripheral devices)

Extra-large-capacity, high-performance

inverter VF-AS1/VF-PS1

These models provide the largest capacity among the Toshiba inverter series inverters.

The sensor-less vector control and PG feedback vector control functions enable high output torque, high-accuracy control for extra-large-capacity motors.

Extra-large-capacity, high-performance

inverter VF-AS1/VF-PS1

About Extra-large-capacity, high-performance

inverter VF-AS1/VF-PS1

Ideal for high-torque, large-capacity equipment such as cranes, hoists, mining machines, refrigerators, press machines, compressors and crushers.

Input voltage class/applicable motor capacity

[VF-AS1]

・Three-phase 200 V input: 90 to 132 kW

・Three-phase 400 V input: 355 to 500 kW

[VF-PS1]

・Three-phase 400 V input: 400 to 630 kW

Features

Applicable to high-torque, large-capacity equipment

The VF-AS1 lineup offers 400 V class models with capacities of up to 500 kW. These models are ideal for high-torque, large-capacity equipment such as cranes, hoists, mining machines, refrigerators, press machines, compressors and crushers.

The VF-PS1 inverter is a 400 V class model supporting a capacity range of up to 630 kW for large-capacity fan and pump applications.

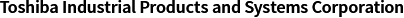

Easy settings

The quick mode, activated by the EASY key, shows only the eight basic parameters, which makes it easy to select and set the parameters.

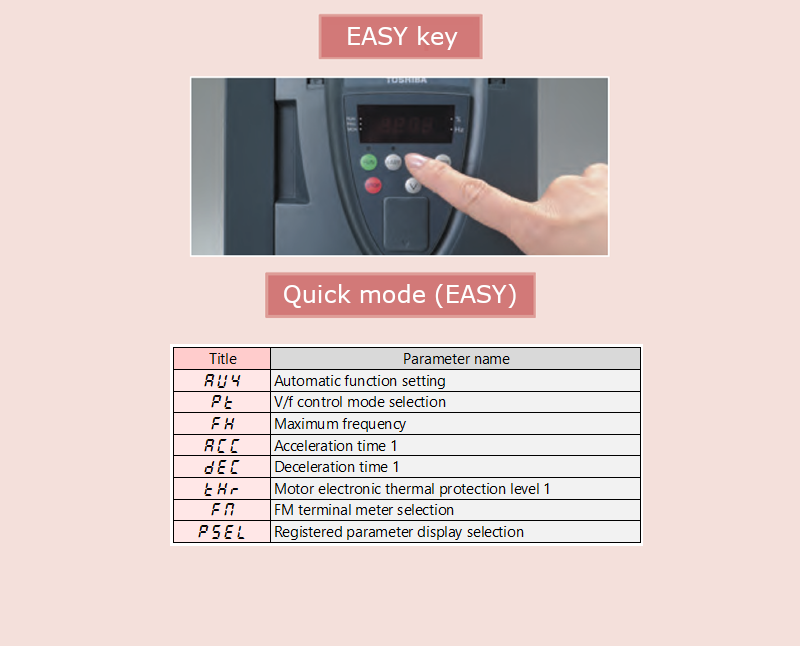

Communication and networks

These models support RS-486 communication as a standard feature, as well as the TOSHIBA protocol and Modbus RTU protocol.

Also, the use of communication options enables support of the main fieldbuses of DeviceNet, PROFIBUS DP and CC-Link.

Adopts

- Dedicated fan and pump functions (VF-PS1)

- Built-in output cutoff function compliant with safety standards (VF-PS1)

- Support of a rich set of options (common to VF-AS1 and VF-PS1)

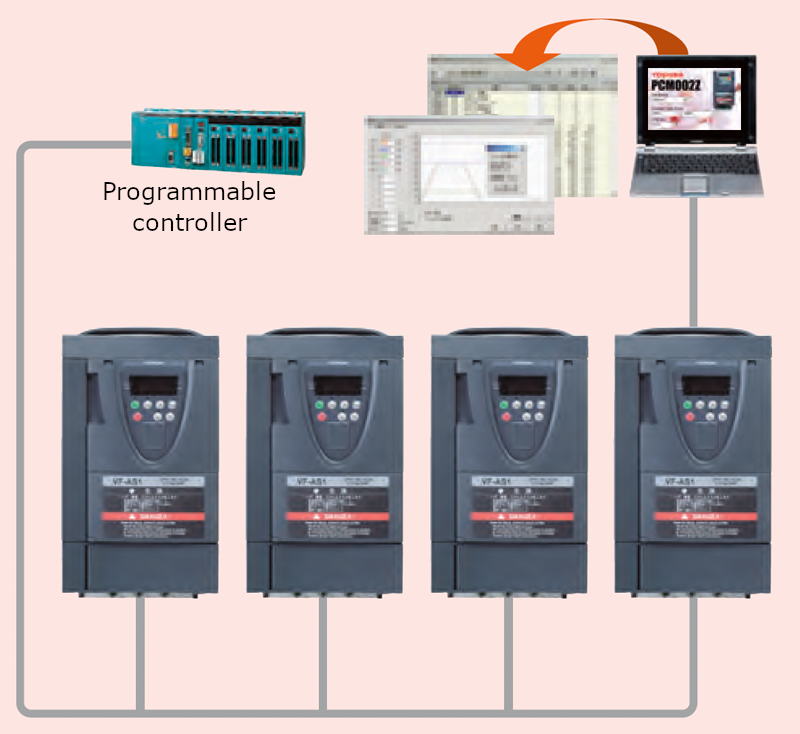

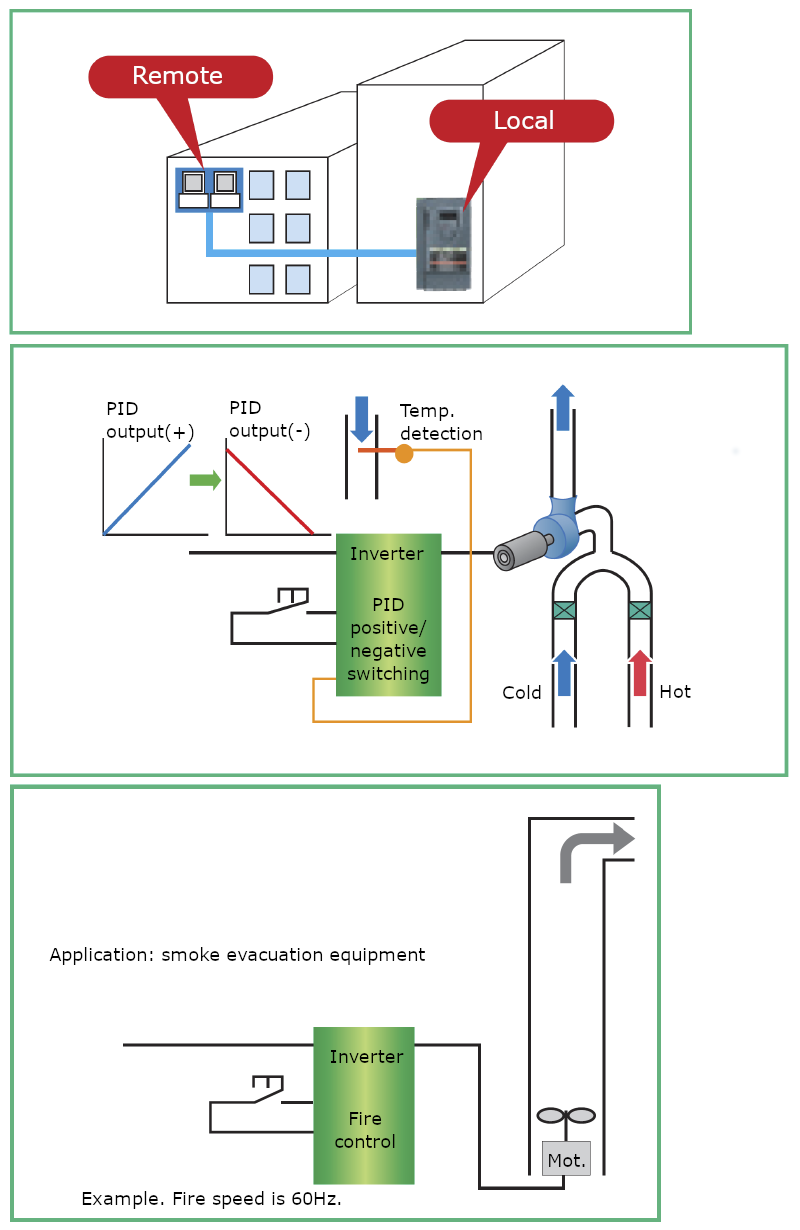

Dedicated fan and pump functions (VF-PS1)

(VF-PS1)

The inverter features dedicated fan and pump functions, such as local/remote mode, PID control with direct/inverse characteristic switching and fire control.

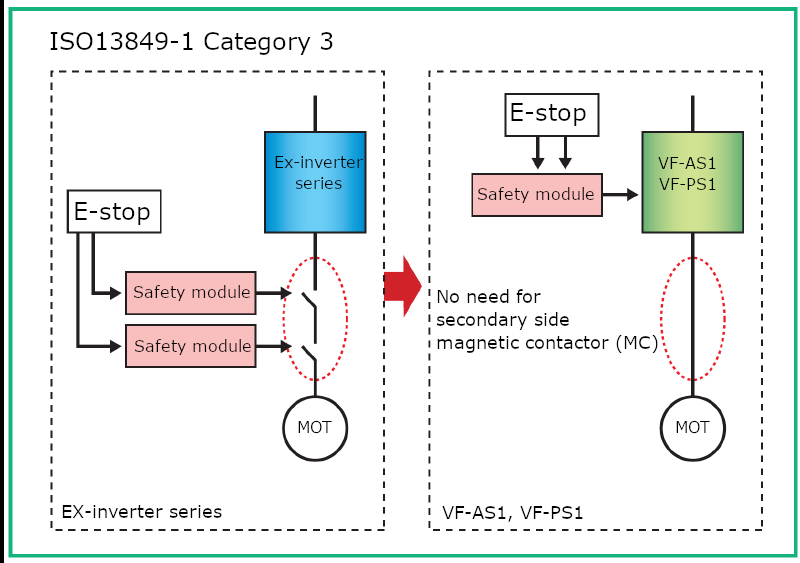

Built-in output cutoff function compliant with safety standards (VF-PS1)

(VF-PS1)

The power removal function (safety function) cuts off the output in compliance with the safety standard for the equipment.

- Compliant with ISO 13849-1 Category 3.

- Compliant with EN 60204-1 Stop Category 0 or 1.

- Compliant with IEC/EN 61508 SIL3.

- Compliant with the EC directive regarding explosion protection (ATEX Directive).

Support of a rich set of options (common to VF-AS1 and VF-PS1)

Dedicated options for VF-AS1 and VF-PS1 are available. For details, contact us.

Performance

- Advanced energy-saving mode (VF-PS1)

- Reduction in harmonic noise

- Suppression of harmonics and improvement in the power factor

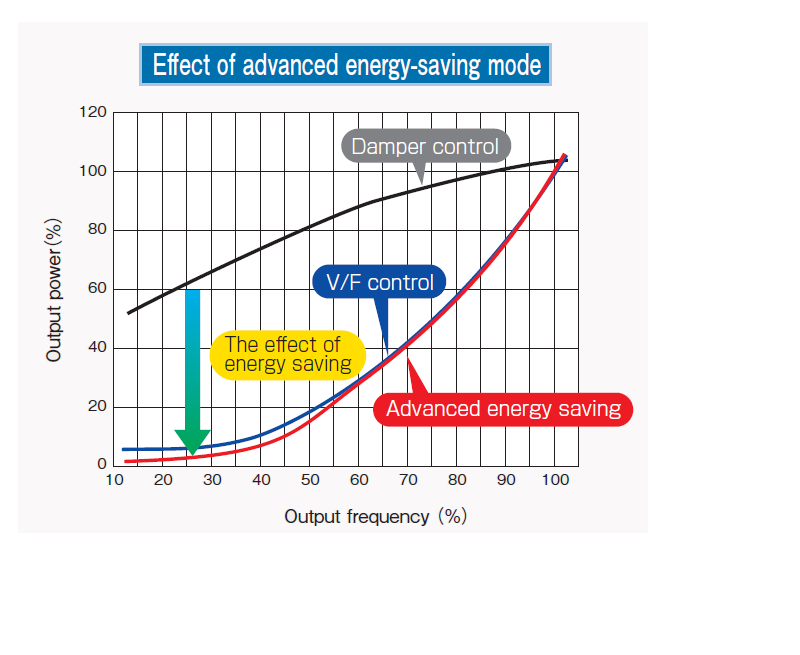

Advanced energy-saving mode (VF-PS1)

The motor efficiency degrades in a low-speed range with a light load.

Control the motor so as to maximize its efficiency even in the low-speed range where the efficiency tends to degrade. This provides a greater energy-saving effect for fans and pumps.

Reduction in harmonic noise

The 400 V class models have a built-in EMC noise filter. The filter reduces harmonic noise substantially, and the inverter achieves compliance with the EU EMC Directive by itself.

Suppression of harmonics and improvement in the power factor

The accompanying or optional DC reactor suppresses harmonics while keeping the input current within 110% of the rated output current. This design is friendly to the power system, including the transformer, no-fuse breaker and wires.

Extra-large-capacity, high-performance inverter VF-AS1/VF-PS1 Spec

| Item | VF-AS1 | VF-PS1 | ||

|---|---|---|---|---|

| Rating | Applicable motor (kW) HD(Heavy Duty) rating | 3-phase 200V input class | 90 to 132kW | |

| 3-phase 400V input class | 355 to 500kW | |||

| 3-phase 690V input class | 110 to 630kW | |||

| Applicable motor (kW) ND(Normal Duty) rating | 3-phase 400V input class | 400 to 630kW | ||

| 3-phase 690V input class | 110 to 630kW | |||

| Overload current rating (HD rating) | 150% - 1 minute | |||

| Overload current rating (ND rating) | 120% - 1 minute | |||

| Dynamic braking circuit | Option | Option | ||

| Power supply (Voltage - frequency) | 3-phase 200V input class | 3-phase 200V to 240V, 50/60Hz | ||

| 3-phase 400V input class | 3-phase 380V to 440V, 50Hz 3-phase 380V to 480V, 60Hz | 3-phase 380V to 440V, 50Hz 3-phase 380V to 480V, 60Hz | ||

| 3-phase 690V input class | 3-phase 500 V to 690 V, 50/60 Hz | 3-phase 500 V to 690 V, 50/60 Hz | ||

| Power supply (Allowable fluctuation) | Voltage: -15%, +10%, frequency: +/-5% | Voltage: -15%, +10%, frequency: +/-5% | ||

| Degree of protection (IEC60529) | IP00 | IP00 | ||

| Cooling method | Forced air-cooled | Forced air-cooled | ||

| EMC filter (IEC61800-3) | Embedded / - *B | Embedded | ||

| DC reactor | Attached optional DC reactor / External optional AC rector *A | Attached optional DC reactor / External optional AC rector *A | ||

| Control specifications | Output frequency range | 0.01 to 500Hz | 0.01 to 500Hz | |

| Minimum setting steps of frequency | 11 bits | 11 bits | ||

| Frequency accuracy | Analogue | +/-0.2% of the maximum output frequency | +/-0.2% of the maximum output frequency | |

| Digital | +/-0.01% of the output frequency | +/-0.01% of the output frequency | ||

| Voltage/frequency characteristics | V/f constant, Variable torque, Automatic torque boost, Sensorless vector control, PM motor control, V/f 5-point setting, PG feedback control, PG feedback vector control | V/f constant, Variable torque, Automatic torque boost, Sensorless vector control, Energy savings, Dynamic energy savings, PM motor control, V/f 5-point setting | ||

| Interface specifications | Digital input | 15 (8: option) | 15 (8: option) | |

| Digital output | 6 (4: option) | 6 (4: option) | ||

| Pulse train frequency input | 1 (option) | 1 (option) | ||

| Pulse train frequency output | 1 (selectable PTO / digital output) | 1 (selectable PTO / digital output) | ||

| Relay output | 3c (2c: option) | 3c (2c: option) | ||

| Analogue input | 5 (2: option) | 5 (2: option) | ||

| Analogue output | 4 (2: option) | 4 (2: option) | ||

| PTC input | 2 (option) | 3 (PTC/AI, 2: option) | ||

| Control power supply | Output | 10Vdc - 10mA | 10Vdc - 10mA | |

| 24Vdc - 200mA | 24Vdc - 200mA | |||

| Input | 24Vdc - 1A | 24Vdc - 1A | ||

| Functional safety | Safe Torque Off comply with IEC61800-5-2 | Safe Torque Off comply with IEC61800-5-2 | ||

| Communication | Embedded | RS485: 2 channel (Toshiba inerter protocol, Modbus RTU) | RS485: 2 channel (Toshiba inerter protocol, Modbus RTU) | |

| Option | DeviceNet | DeviceNet | ||

| PROFIBUS DP | PROFIBUS DP | |||

| CC-Link | CC-Link | |||

| Environment | Ambient temperature | -10 to +60 °C *1 | -10 to +60 °C *1 | |

| Storage temperature | -25 to +70 °C (Temperature applicable for a short term.) | -25 to +70 °C (Temperature applicable for a short term.) | ||

| Relative humidity | 5 to 95% (free from condensation) | 5 to 95% (free from condensation) | ||

| Altitude | 3000m or less *2 *3 | 3000m or less *2 *3 | ||

| Vibration | 5.9m/s2 (0.6G) or less (10 to 55Hz) | 5.9m/s2 (0.6G) or less (10 to 55Hz) | ||

*1: Over 40°C, need current reduction

*2: Need current reduction over 1000m

*3: Depends on earthing system

| *A Attached optional DC reactor VFAS1-2900P to 2132KP, 4355KPC to 4500KPC External optional AC rector (instead of DC reactor)VFAS1-6110KPC to 6630KPC |

| *B without noise filter: VFAS1-2900P to 2132KP EMC filter:VFAS1-4355KPC to 4500KPC |

*1: Over 40°C, need current reduction

*2: Need current reduction over 1000m

*3: Depends on earthing system

| *A Attached optional DC reactor VFPS1-4400KPC to 4630KPC External optional AC rector (instead of DC reactor)VFPS1-6110KPC to 6630KPC |

Input voltage classes and applicable motor capacity range

[VF-AS1] Overload capacity: 150% for 1 minute

Three-phase 200 V at 90 to 132 kW, three-phase 400 V at 355 to 500 kW

[VF-PS1] Overload capacity: 120% for 1 minute

Three-phase -400 V at 400 to 630 kW