- InverterTop

- Inverter

- Inverter options (peripheral devices)

Multifunction and compact inverter VF-S15

This series offers a multifunction and compact midrange model among the Toshiba inverter series inverters. It fulfills a range of purposes from energy savings for equipment to support of high performance.

Multifunction and compact inverter VF-S15

About Multifunction and compact inverter VF-S15

Developed with the focus on "easy settings and operation," "eco-friendly design," "energy-saving and powerful operation," "applicability" and "system scalability," this inverter can be used for a wide range of applications from fans and pumps to lifting machines.

Input voltage class/applicable motor capacity

・Single-phase 240 V input: 0.2 to 2.2 kW

・Three-phase 240 V input: 0.2 to 15 kW

・Three-phase 500 V input: 0.4 to 22 kW

・Three-phase 600 V input: 0.4 to 15 kW

Features

- Easy settings and operation

- Eco-friendly design

- Energy saving and powerful operation

- Applicability

- System scalability

Easy settings and operation

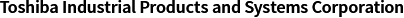

・The large setting dial allows you to set the parameters at once.

Turn the setting dial on the operation panel and push its middle part to select the settings.

The large setting dial can also be used for the frequency setting.

・The EASY key shows only the frequently used parameters.

Using the EASY key, you can toggle between two modes (standard and easy).

Eco-friendly design

・Long-life design

The use of a long-life main circuit capacitor and other components offers an expected design life of as many as 10 years.

・Harmony with the environment

The inverter complies with the EU RoHS Directive (2011/65/EU) restricting six substances, as well as the revised EU RoHS Directive (2015/863).

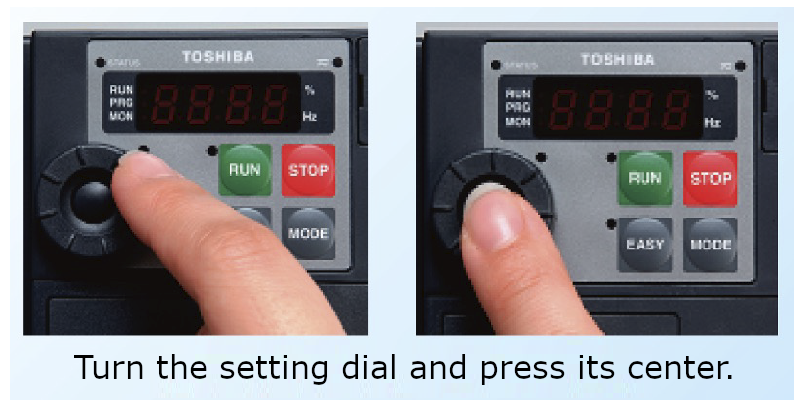

・Safety function for cutting off the output with high reliability

The STO (Safe Torque Off) function compliant with the relevant safety standards can cut off the output.

Energy saving and powerful operation

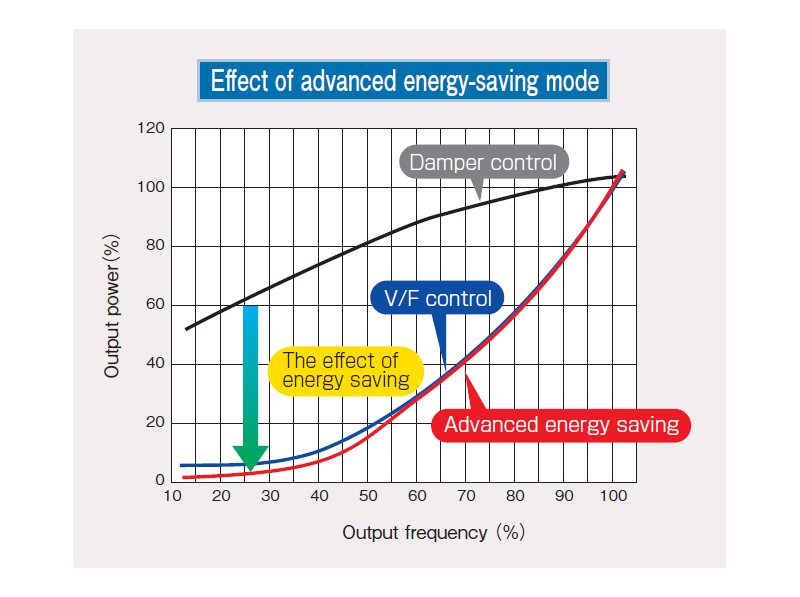

・Saving energy in collaboration with a motor

The inverter has a standard feature to drive a highly energy-efficient PM motor.

Also, an automatic energy-saving mode is available for induction motors for a greater energy-saving effect.

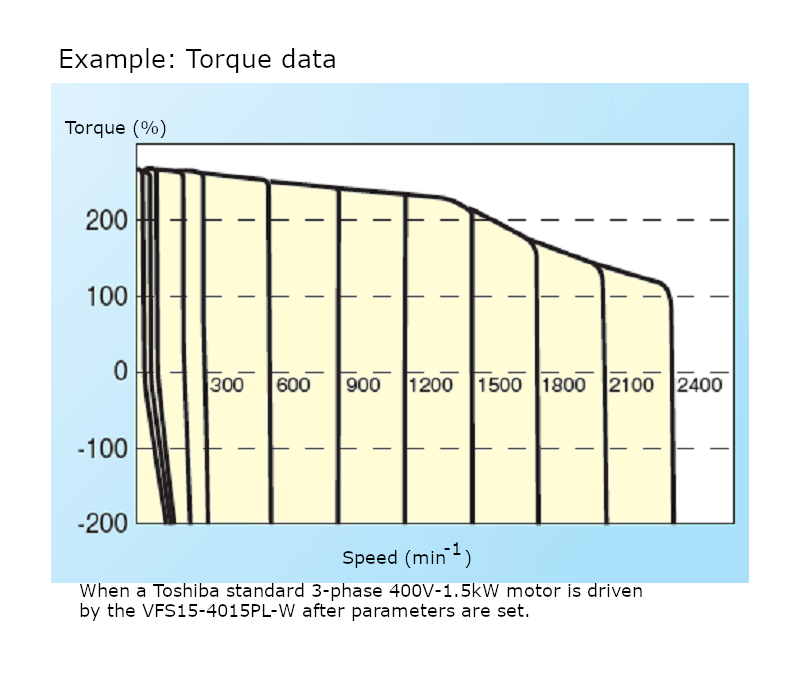

・Stable operation of a high-torque load

Vector control allows high-torque operation to be performed from the start until the rated frequency is reached.

Applicability

・Auto-tuning for easy motor constant settings

This function allows you to easily set the motor constants necessary for vector control and PM motor control, bringing out the best motor performance.

・Teaching function for easy adjustment of lifting machines

The teaching function makes it easy to adjust the parameters of the brake sequence and light-load high-speed operation functions of a lifting machine as appropriate for the machine.

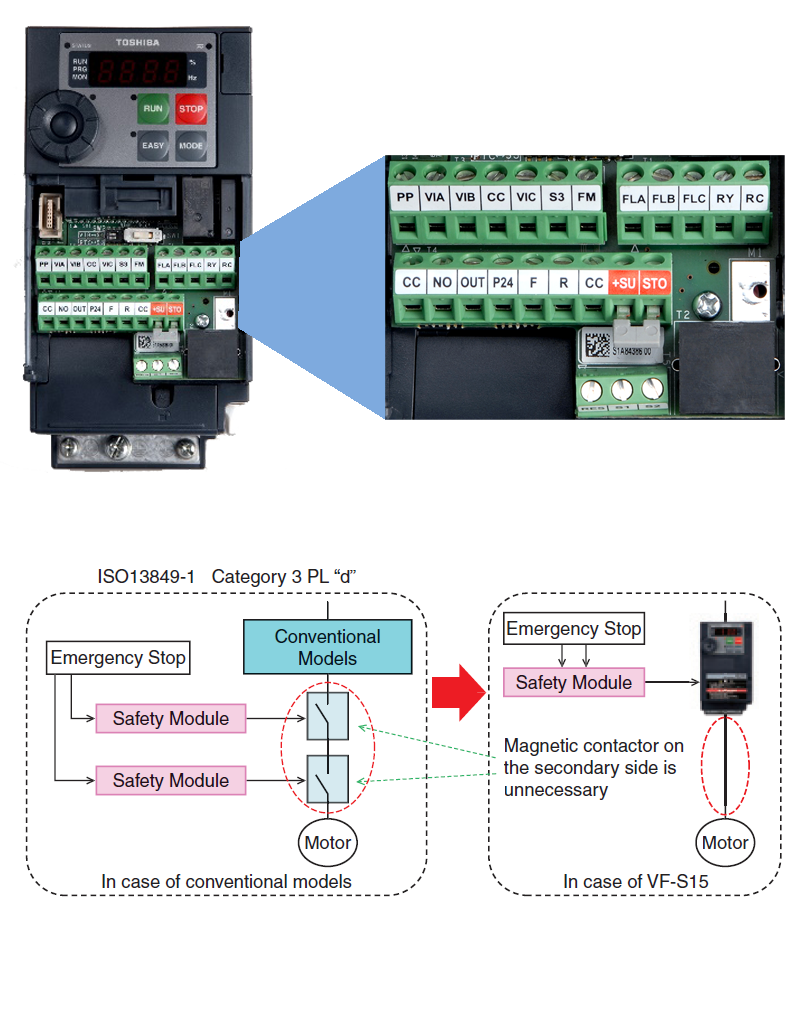

System scalability

・The RS485 communication function is supported as a standard feature.

The Modbus RTU protocol and Toshiba protocol are supported.

Communication speed: Max. 38.5 kbps

・Rich set of network options

CC-Link, PROFIBUS DP, PROFINET, DeviceNetTM, EtherNet/IPTM, EtherCAT® and CANopen® are supported.

・A simple programming function "My Function-S" is available.

Adopts

- The inverter can also be operated with a PM motor manufactured by another company.

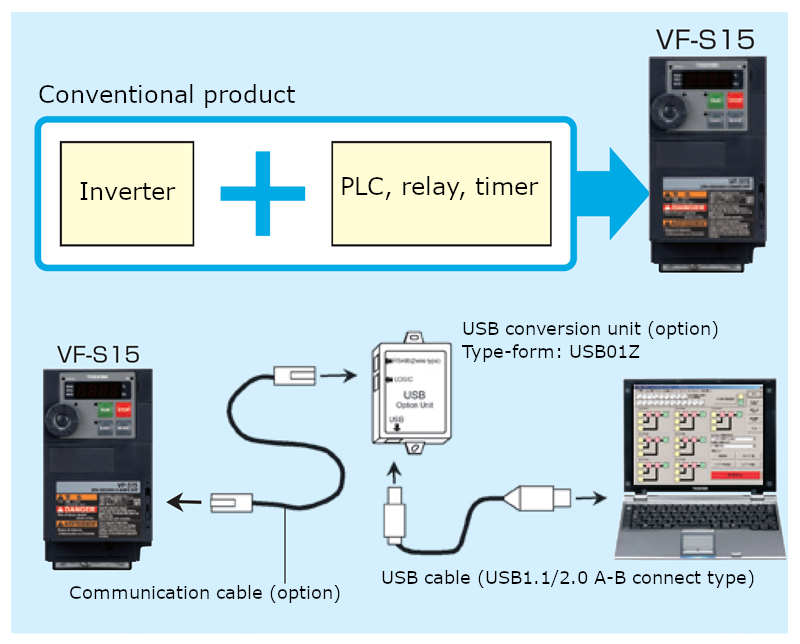

- A simple programming function "My Function-S" simplifies the system.

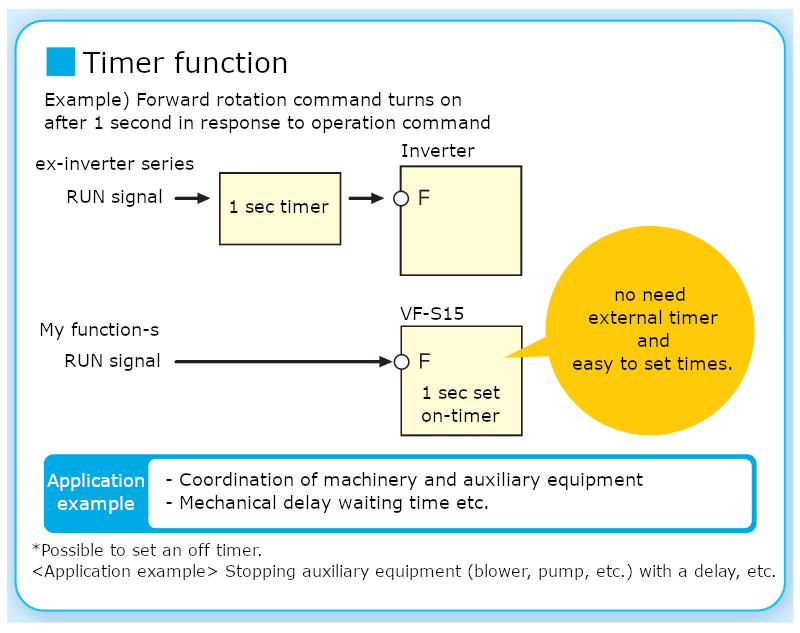

- Usage example ①: Omission of the external timer

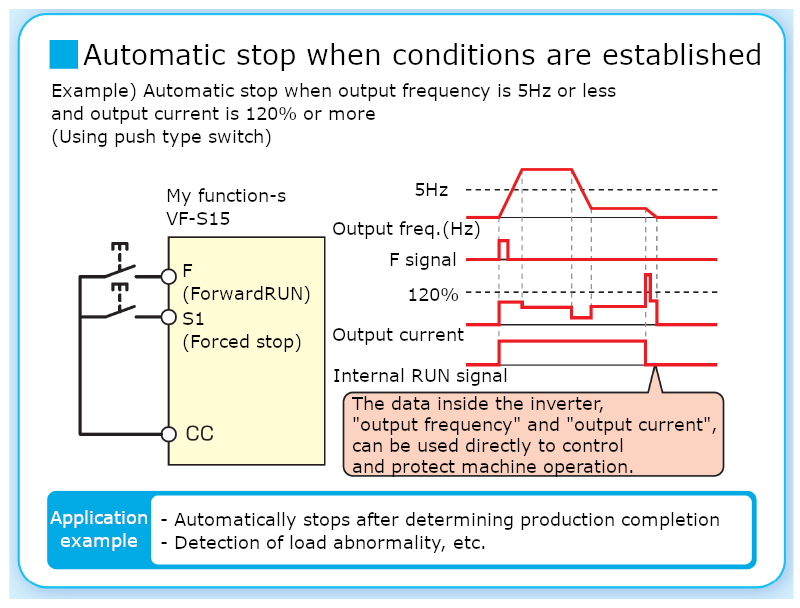

- Usage example ②: Built-in auto-stop function

- Reduction in the adjustment time and improvement in machine performance

The inverter can also be operated with a PM motor manufactured by another company.

Not only Toshiba PM motors but also PM motors manufactured by other companies can be driven easily using the auto tuning function.

A simple programming function "My Function-S" simplifies the system.

My Function-S handles part of the external circuit consisting of relays, PLC and other components inside the inverter.

Also, the dedicated software (PCL001Z) allows you to set the My Function-S parameters with ease.

Usage example ①: Omission of the external timer

Usage example of My Function-S ①

In response to an operation command, the normal rotation command turns on after one second.

Usage example ②: Built-in auto-stop function

Usage example of My Function-S ②

The inverter automatically stops when the output frequency is below 5 Hz and the output current is over 121% (the push switch is used).

Reduction in the adjustment time and improvement in machine performance

The teaching function makes it easy to adjust the parameters of the brake sequence and light-load high-speed operation functions of a lifting machine as appropriate for the machine, thereby improving the machine performance.

Performance

- Energy-saving effect and CO2 reduction

- Saving energy in collaboration with a motor

- Stable operation of a high-torque load

- Capable of cutting off the output in compliance with safety standards

Energy-saving effect and CO2 reduction

When the inverter controls the air volume and flow rate of the general fans and pumps, the shaft power lowers, which saves energy.

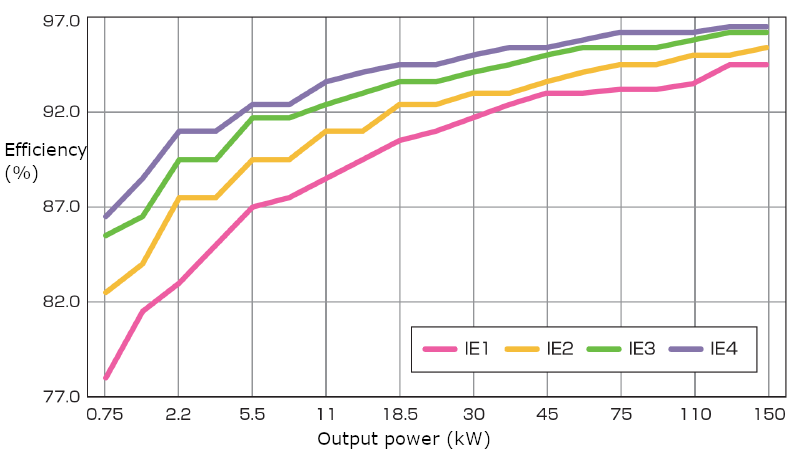

Saving energy in collaboration with a motor

The Toshiba PM motors achieves an efficiency level equivalent to the IE4 super premium efficiency, the highest efficiency level defined in IEC 60034-30. It represents an increase of 3 to 14% in efficiency from the IE1 efficiency level.

Stable operation of a high-torque load

Vector control allows high-torque operation to be performed from the start until the rated frequency is reached. In addition, setting the start frequency to 0.1 Hz causes the inverter to start operating powerfully.

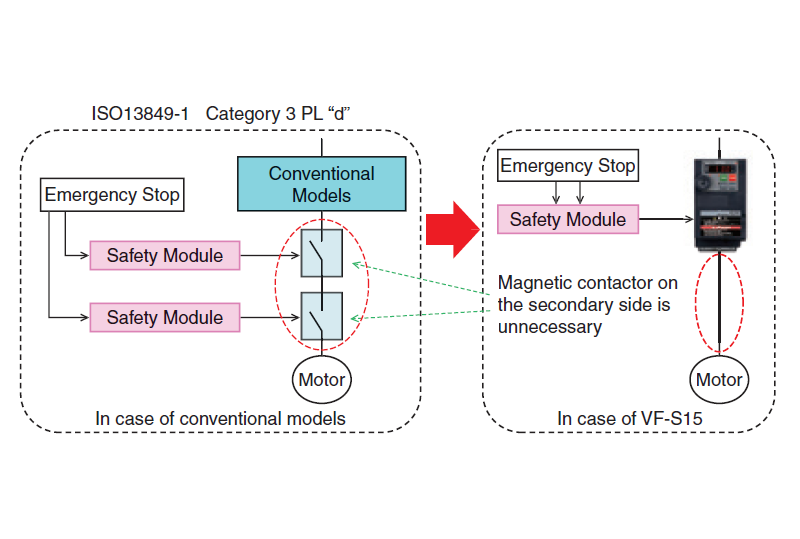

Capable of cutting off the output in compliance with safety standards

The STO (Safe Torque Off) function compliant with the relevant safety standards can cut off the output with high reliability in an emergency.

Also, the use of the safety function built in the inverter simplifies the system, leading to cost savings.

Multifunction and compact inverter VF-S15 Spec

| Item | VF-S15 | ||

|---|---|---|---|

| Rating | Applicable motor (kW) HD(Heavy Duty) rating | Single-phase 240V input class | 0.2 to 2.2kW |

| 3-phase 240V input class | 0.2 to 15kW | ||

| 3-phase 500V input class | 0.4 to 22kW | ||

| 3-phase 600V input class | 1.5 to 15kW | ||

| Overload current rating (HD rating) | 150% - 60 seconds, 200% - 0.5 second | ||

| Dynamic braking circuit | Embedded | ||

| Power supply (Voltage - frequency) | Single-phase 240V input class | Single-phase 200V to 240V, 50/60Hz | |

| 3-phase 240V input class | 3-phase 200V to 240V, 50/60Hz | ||

| 3-phase 500V input class | 3-phase 380V to 500V, 50/60Hz | ||

| 3-phase 600V input class | 3-phase 525V to 600V, 50/60Hz | ||

| Power supply (Allowable fluctuation) | Voltage: -15%, +10%, frequency: +/-5% | ||

| Degree of protection (IEC60529) | IP20 | ||

| Cooling method | Self-cooling / Forced air-cooled *A | ||

| EMC filter (IEC61800-3) | Embedded / - *B | ||

| DC reactor | Option | ||

| Control specifications | Output frequency range | 0.1 to 500Hz | |

| Minimum setting steps of frequency | 10 bits | ||

| Frequency accuracy | Analogue | +/-0.5% of the maximum output frequency | |

| Digital | +/-0.01% of the output frequency | ||

| Voltage/frequency characteristics | V/f constant, Variable torque, Automatic torque boost, Sensorless vector control, Energy savings, Dynamic energy savings, PM motor control, V/f 5-point setting | ||

| Interface specifications | Digital input | 8 (2: selectable digital input / analogue input) | |

| Digital output | 1 | ||

| Pulse train frequency input | 1 (selectable PTI / digital input) | ||

| Pulse train frequency output | 1 (selectable PTO / digital output) | ||

| Relay output | 1c, 1a | ||

| Analogue input | 3 | ||

| Analogue output | 1 | ||

| PTC input | 1 (selectable PTC input / disital input) | ||

| Control power supply | Output | 10Vdc - 10mA | |

| 24Vdc - 100mA | |||

| Input | 24Vdc - 1A | ||

| Functional safety | Safe Torque Off comply with IEC61800-5-2 | ||

| Communication | Embedded | RS485: Toshiba inerter protocol, Modbus RTU | |

| Option | DeviceNet | ||

| PROFIBUS DP | |||

| EtherCAT | |||

| CC-Link | |||

| EtherNet/IP - Modbus TCP | |||

| PROFINET | |||

| CANopen | |||

| Environment | Ambient temperature | -10 to +60 °C *1 | |

| Storage temperature | -25 to +70 °C (Temperature applicable for a short term.) | ||

| Relative humidity | 5 to 95% (free from condensation) | ||

| Altitude | 3000m or less *2 | ||

| Vibration | 5.9m/s2 (0.6G) or less (10 to 55Hz) | ||

*1: Over 40°C, remove top-seal and need current reduction

*2: Need current reduction over 1000m

| *A Self-cooling: VFS15S-2002PL-W1 to 2007PL-W1 Forced air-cooled:VFS15-2002PM-W1 to 2007PM-W1 VFS15S-2015PL-W1, 2022PL-W1 VFS15-2015PM-W1 to 2150PM-W1 VFS15-4004PL-W1 to 4220PL-W1 VFS15-6015P-W1 to 6150P-W1 |

| *B Basic filter: VFS15-2002PM-W1 to 2150PM-W1 EMC filter:VFS15S-2002PL-W1 to 2022PL-W1 Without filter:VFS15-4004PL-W1 to 4220PL-W1 VFS15-6015P-W1 to 6150P-W1 |

Input voltage classes and applicable motor capacity range

Single-phase 240 V input: 0.2 to 2.2 kW

Three-phase 240 V input: 0.2 to 15 kW

Three-phase 500 V input: 0.4 to 22 kW

Three-phase 600 V input: 0.4 to 15 kW

Overload capacity: 150% for 1 minute