- MotorTop

- Premium gold motor

- Gear motor

- Brake motor

- Explosion-proof type motor

- The other motors, Peripheral equipment

Brake motor (SBD-H series)

The SBD-P series brake motor, which inherits the history of Toshiba gear motors, has been reborn as the SBD-H series brake motor, thanks to the high efficiency technology of the premium gold motor.

Brake motor (SBD-H series)

About Brake motor (SBD-H series)

The SBD brake is a spring-controlled three-phase induction motor with a DC electromagnetic brake. It is a non-excitation (spring-controlled) brake, which is suitable for use during a power outage or emergency stop. With its stable control performance, the brake meets the diverse needs of many types of industrial equipment. It uses the premium gold motor, which means this product is compliant with the Top Runner standard.

Features

- Compliant with the Top Runner standard. (Excluding the 0.4-kW model)

- Installation compatibility with the existing SBD-P series is provided.

- Easy maintenance and inspection

- Excellent response

- Inverter drive

Compliant with the Top Runner standard. (Excluding the 0.4-kW model)

It is equipped with a brake featuring the premium gold motor, which means this motor is compliant with the Top Runner standard.

The motor can be expected to provide a significant energy-saving effect compared to standard efficiency motors.

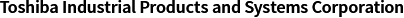

Installation compatibility with the existing SBD-P series is provided.

Replacement is easy because the frame size is the same as that of the existing SBD-P series.

(In some models, the total length may be longer.)

Easy maintenance and inspection

The unit-type brake part can be detached from the motor, and the manual releasing device (bolt type) enables easy maintenance.

Excellent response

The use of a high-performance brake power unit ensures excellent braking response even in the case of the simultaneous releasing configuration.

While the simultaneous releasing configuration is used by default, the separate releasing configuration enables even faster response.

Inverter drive

All PGM-equipped models of 0.75 kW and higher support inverter-driven constant torque operation within the range of 1:10.

(Operating an inverter requires changing the DC power unit and the circuit configuration.)

Adopts

- The motor is compliant with the Top Runner standard, and its energy-saving effect reduces environmental impact.

- Installation compatibility

- Excellent response

- Insulation class

- Inverter drive is possible.

The motor is compliant with the Top Runner standard, and its energy-saving effect reduces environmental impact.

Compared to our existing standard motor, loss is reduced by 30 to 40%. The energy-saving effect resulting from increased efficiency contributes to reducing environmental impact.

Installation compatibility

Replacement is easy because the installation dimensions are the same as those of the existing SBD-P series.

(The motor-side total length is longer as a result of making the motor more efficient.)

Excellent response

The spring-controlled multi-disc brake uses a lining material with significant braking work and has abundant braking torque, providing stable braking performance over an extended period of use.

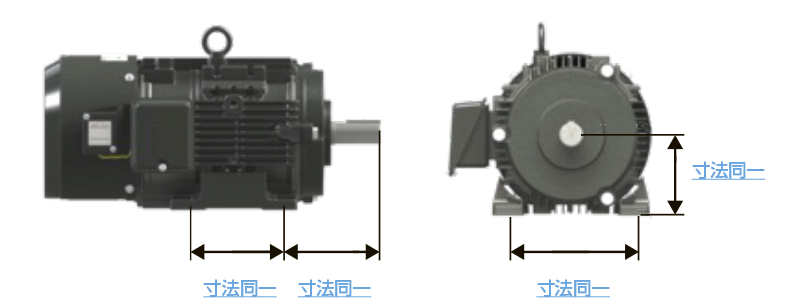

Insulation class

The PGM-equipped models have Class 155 (F) insulation and limit temperature rises to 80 K (Class B), and the high insulation reliability is expected to increase their service life. The brake coil also has Class F insulation, resulting in higher reliability.

(Excluding the 0.4-kW model)

Inverter drive is possible.

All PGM-equipped models of 0.75 kW and higher support inverter-driven constant torque operation within the range of 1:10.

(Operating an inverter requires changing the DC power unit and the circuit configuration.)

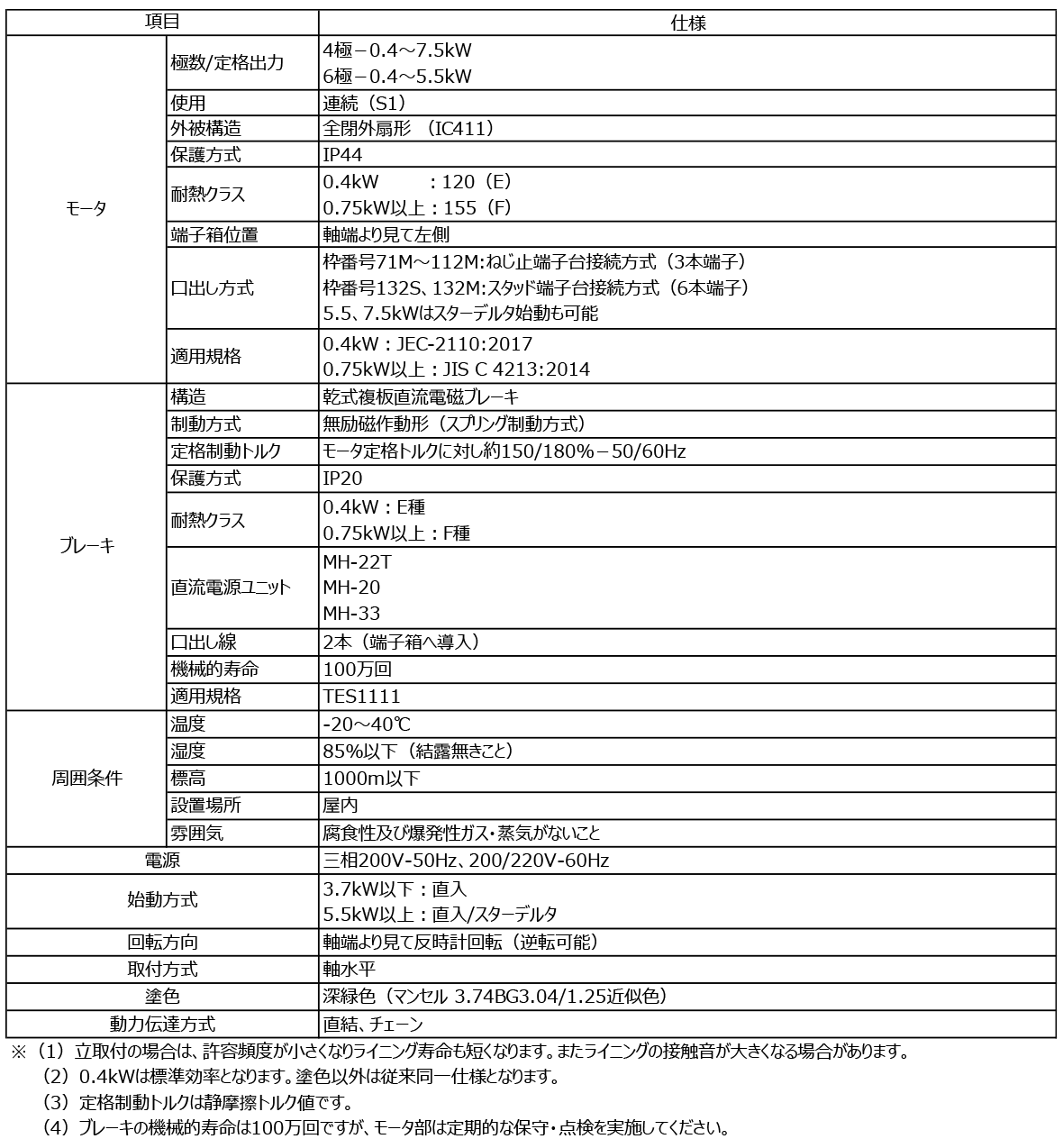

Brake motor (SBD-H series) Spec

SBD-H series 4-pole at 0.2 to 7.5 kW, 6-pole at 0.4 to 5.5 kW